The best time to install a frost-free sillcock is before it gets cold enough to frost. That means summer is the perfect time to plan this reasonably simple project. Materials are affordable, and even a beginner can follow these steps to install the sillcock.

If you’re tired of shutting off your outdoor water supply every winter, a freeze-proof anti-siphon sillcock is all you need.

Materials Required for a Frost-Free Sillcock

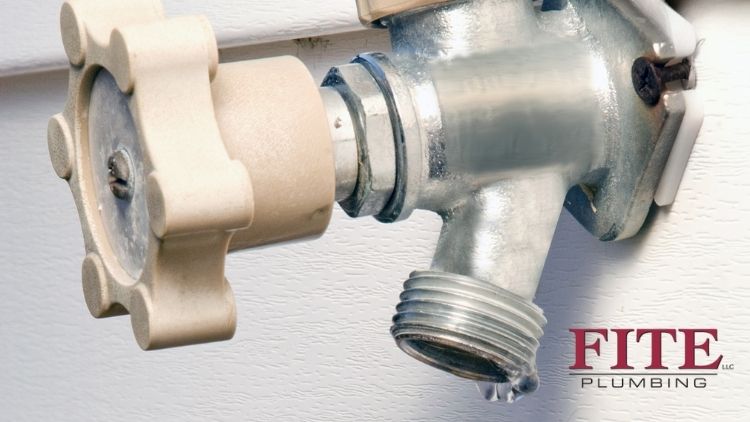

A sillcock is an outdoor faucet, so the first item on your list should be one of these. Make sure it’s freeze-proof and for outdoor use. It should also have an anti-siphon device. The anti-siphon device is important because it’s a vacuum breaker. This is what you need to prevent contaminated water from being siphoned back into your outdoor water supply.

To install a frost-free sillcock, you’ll also need:

- Lead-free solder

- Flux (Paste you apply to copper pipe and fittings)

- Pipe cutter

- Propane Torch

- Black sanding cloth (Emery cloth)

- Bucket of rags

- Pipe hanging devices (As needed, every five or six feet)

- *Copper pipe (3/4” inside diameter)

- Copper elbows (90 and 45-degree)

*If your plumbing system doesn’t use copper material, buy a reducer or adapter to connect the sillcock properly.

Choose Location for Sillcock

The best way to choose the location for your frost-free sillcock is by looking for the penetration points where telephone lines, service cables, or pipes are entering the house. You’ll want to find these places so you can install the sillcock near them, ensuring you the path of least resistance when getting through the house’s foundation or siding.

After choosing your location on the outside, find the spot where it will enter inside your house. This is also to make sure you won’t be cutting into an inappropriate location. This may also be the time you decide it’s time to call Fite Plumbing.

Steps to Install a Frost-Free Sillcock

Now it’s time to install the sillcock.

- Place the angled siding wedge between the siding and the sillcock. The angle guarantees that everything drains downwards.

- Use the sanding cloth to clean pipe ends and the inside of fittings.

- Apply flux liberally to the insides of the fittings and the ends of the pipe.

- Make sure new pipe sections are the right length, and then connect all fittings.

- Line up the cold water pipe and the center of the copper tee and mark back a one-half inch from both ends.

- Using a pipe cutter, cut the short section of pipe and then dry ends thoroughly with some old rags and then apply flux.

- Install the tee in between cold water pipes and assemble the remaining section. Before soldering, make sure the faucet is angled down.

- Using your lead-free solder, it’s time to solder all the joints. Your sillcock faucet should be open so pressure doesn’t build up. Plus, that way the rubber washers won’t burn when the internal air temperature rises.

Here are a few more tips before starting. The old saying is true: Measure twice, cut once.

Work backward so that the installation point is appropriate. Double-check what kind of material you’ll need and get extra in case of mistakes. Don’t forget to shut off your water meter. Finally, plan the pipe route before measuring and assembling.

One final trick that might surprise you is how to keep your pipe ends dry while working. Use a balled-up piece of white bread stuffed inside both ends. The bread won’t plug anything up or harm your system, and the bread absorbs water.

Of course, if all of this sounds like too much, call the plumbing professionals at Fite Plumbing at 317-271-5400 today for expert help.

Are you on Facebook? We are, too. Let’s be friends!